The shareholders also approved the following:

- The change of name of the Company to “BluMetric Environmental Inc.”

- The consolidation of the common shares of the Company on a 1-for-10 basis

- The reduction in stated capital of the Company to $1

- An amendment to the Share Option Plan of the Company increasing the number of shares that may be issued thereunder to 3,200,000 (after giving effect to the share consolidation). Certain Insiders and their affiliates were excluded from voting on the amendment.

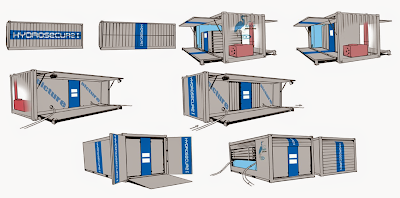

The CLEMENTINE® is a wastewater plant in a standard 20’ ISO container. Designed

for transport by land, sea and air, this extremely versatile machine is purpose built to

be transported just about anywhere under just about any conditions. There are no

exterior tanks, holding ponds or exterior components. Quiet and free of unpleasant

odours, this is the perfect wastewater solution for hard to get to remote sites and

temporary camps or installations.

CLEMENTINE® is a complete wastewater treatment plant in a box. Everything needed

to treat wastewater is in the single unit. This plant is a plug and play system that is very

easy to operate and maintain. If you can operate a portable generator then you can

operate a CLEMENTINE®. See specifications on reverse.

Some ideal applications for the CLEMENTINE® are:

- Mining camps

- Military camps

- Construction camps

- Oil rigs and pipelines

- Areas accessible only by air

- Environmental emergencies

- Foreign relief missions

- Temporary municipal services